The Hall Company prides itself on offering the highest quality membrane switches available on the market. Our experience designing and manufacturing custom membrane switches goes back to the late 1970’s and The Hall Company was awarded one of the earlier patents for membrane switch assemblies. The Hall Company’s decades of experience help to ensure that your product’s design will function correctly in whatever environment you need it to operate in. Membrane switches can be used in a variety of products and applications and are an economical solution for a multitude of switching needs. The Hall Company produces membrane switches for global leaders in the medical, aviation, consumer, industrial, food service, and scientific markets. The Hall Company does extensive life cycle testing on its membrane switch products to ensure customer expectations are exceeded.

traditional mechanical switch. Membrane switches are also easy to clean and have less opportunities for water intrusion making them ideal for a variety of industries. Some examples of membrane switches might be controls for consumer appliances, key pads at gas pumps, and controls on a lot of medical devices. Membrane switches can be very thin and can offer almost any key configuration needed. Membrane switches operate when two layers of printed circuitry and pressed together closing the circuit normally open circuit.

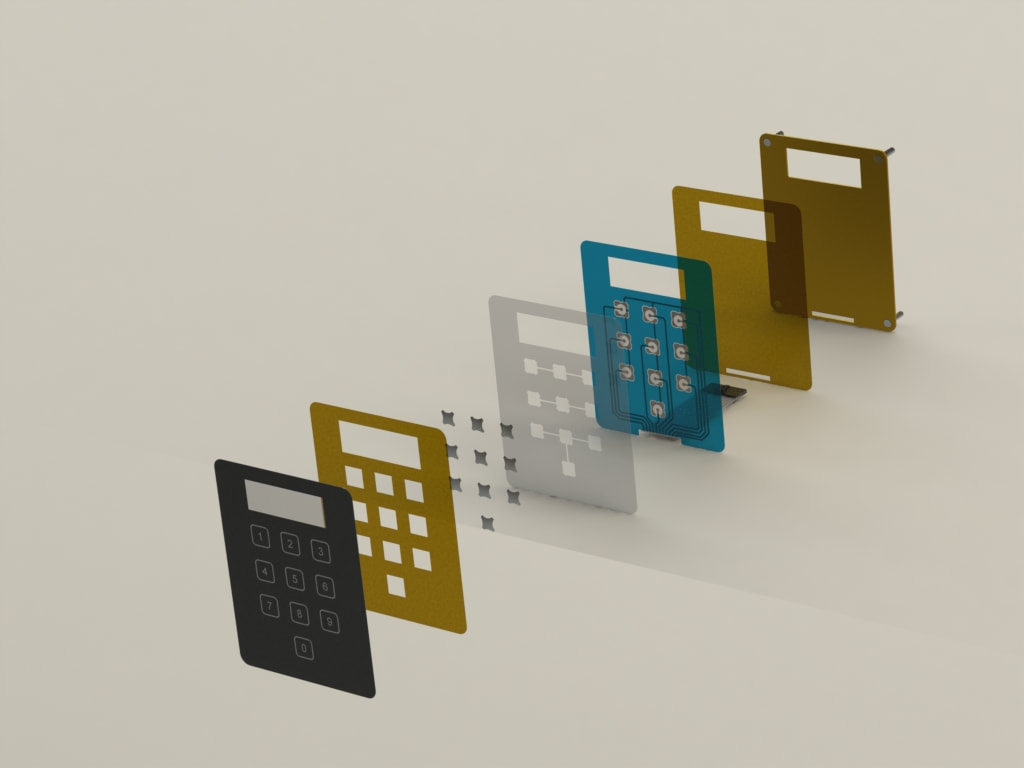

Membrane Switch Construction Membrane switches made up of thin flexible plastic layers including polyesters and polycarbonates. These layers are built up and sandwiched together to construct the whole switch assembly. Membrane switch construction ranges from fairly simple to very complex depending on the switches functionality and the environment it will be required to operate in. At a minimum, the switch assembly would require a printed graphical overlay, adhesive layers, a printed upper circuit layer, spacer materials, a printed lower circuit layer, another adhesive layer, and filler for the termination tail. More complex assemblies can include backlighting layers, dome layers, shielding layers, and other layers for various product requirements. Membrane switch circuits are screen printed using silver or carbon conductive inks to create a circuit layer. Graphical layers can be either screen printed or digitally printed. Metal domes can be added to provide tactile feedback to the user. LEDS can be used in conjunction with other materials to backlight a membrane switch. Membrane switches can also be completely flexible circuit assemblies, adhered to a backplate, or built up on top of a rigid PCB. Membrane Switch Uses Because of their slim profile, economic efficiency, and versatility, membrane switches are used in a variety of industries. Some examples include: Medical industry– because of their ease of cleaning, ability to withstand moisture intrusion, and reliability, membrane switches are regularly used in medical devices. Aviation industry– membrane switches light weight and low profile make them ideal for aviation solutions from the cabin to the cockpit of commercial and private aircraft. Industrial controls– membrane switches are well suited for harsh environments and are easily cleaned making them common in industrial applications. Food Equipment – membrane switches can be an ideal solution for food preparation and handling equipment because of their low profile, reliability and ease of cleaning. Consumer Applications– membrane switches are ideal for consumer applications because of their cost effectiveness, slim size, unlimited design options, and backlighting abilities. Scientific and Electrical Equipment – Membrane Switches are widely used in both scientific equipment and electronics because of their ease of cleaning, ability to withstand moisture intrusion, and slim profiles. |

Membrane Switch Options

|